Electroless nickel (EN) plating is known for its superior corrosion and wear resistance, low cost, uniform thickness, and ability to plate on large and complex substrates. EN plating is a widely used surface treatment method in many industries such as aerospace, construction, and electronics—particularly in the manufacturing process of PCBs (printed circuit boards). To ensure that a high-quality coating is produced and the desired specifications are met, several parameters must be monitored during the electroless nickel plating process. This article describes how mercury-free sensors from Metrohm can be used to monitor the concentration of stabilizers (e.g., Pb, Sb(III), and Bi) in electroless Ni plating baths.

Overview of the electroless Ni plating process

Electroless nickel plating is known as a chemical or autocatalytic plating process. EN plating is based on the deposition of nickel alloys on different substrates without the use of electric current. The process takes place in a specific Ni plating bath, such as that in Figure 1. An electroless nickel plating bath typically contains several key components including Ni salts, reducing agent, pH adjuster, stabilizers, and complexing agent. The specific composition of the bath may vary—additional components may be added to achieve specific coating properties or to improve the efficiency of the plating process [1].

The EN plating process proceeds spontaneously once an initial layer of nickel has formed on the surface of the substrate. Stabilizers play an important role in electroless nickel plating solutions as they control the plating rate and prevent uncontrolled plate out (decomposition) of the bath [2]. To achieve desired performance it is important to keep the stabilizer concentration at an optimal level. Significant fluctuations in the nominal stabilizer concentration may affect the deposition rate, bath stability, poison the deposition at the edges, or even stop the plating reaction completely. Monitoring the stabilizer concentration is therefore essential for an optimal plating process.

Voltammetry

Voltammetry (VA) uses electrochemical sensors for the determination of heavy metal ions. By measuring the current as a function of applied potential, it is possible to determine the concentration of different ions in the solution, including Pb, Bi, and Sb(III), which are commonly used as stabilizers in electroless Ni plating baths [3].

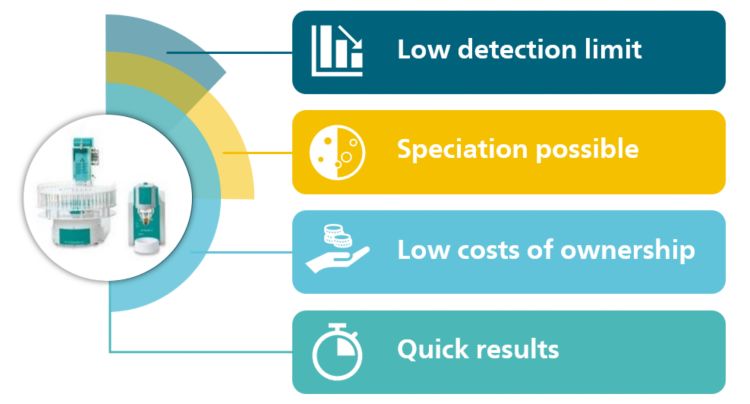

VA has several advantages over other analytical techniques like atomic absorption spectroscopy (AAS) and inductively coupled plasma (ICP) spectroscopy [4]. Some of these benefits include:

- Sensitivity: Voltammetry is able to determine electroactive species in the low ppb (µg/L) or even ppt (ng/L) range. This makes it an ideal technique for monitoring trace levels of ions in EN plating baths.

- Selectivity: As a highly selective technique, VA is able to distinguish between different electroactive species (e.g., Pb, Sb(III), and Bi) in complex matrices like electroless Ni plating solutions.

- Simplicity: Voltammetry is relatively simple to set up and use and does not require the use of a flame or plasma, as is the case with AAS and ICP. This makes it easier to install and to run the VA system even in a production environment.

- Low cost (affordability): Total cost of ownership is significantly lower compared to techniques such as AAS and ICP.

- Portability: VA is able to determine electroactive species easily, even when working in the field.

- Automation: Metrohm instruments used for VA determination are highly flexible and modular. For example, if needed, the manual 884 Professional VA can be equipped with a sample changer, dosing devices, and rinsing pumps. This facilitates fully automated voltammetric determination using the MVA-22 system, as shown in Figure 2.

Voltammetric sensors – with and without Hg

For many years, the hanging mercury drop electrode (HMDE) has been used extensively for the voltammetric determination of heavy metals. The mercury-based electrode is ideally suited for trace metal determination due to its high sensitivity, wide cathodic polarization range, and the automatically renewable and reproducible electrode surface.

Despite its unique properties for electroanalysis, mercury is toxic and can accumulate in living organisms. To reduce the detrimental effect of metallic mercury on the environment, and to replace mercury in the voltammetric determination of heavy metals, mercury-free sensors were required [5]. The term «mercury-free» means that no metallic mercury is utilized.

Metrohm has undertaken great efforts to combat the challenges related to the replacement of Hg in the electrodes used for voltammetric determination of heavy metals. This led to the development of four new mercury-free sensors (Figure 3).

Using Hg-free sensors to monitor stabilizer concentration in an electroless Ni bath

As demonstrated in the White Paper: «Green alternatives for voltammetric analysis in different water samples», the scTRACE Gold and bismuth drop (Bi drop) electrodes have proven their excellent performance for the determination of heavy metals in different aqueous solutions. In addition to water samples, they can be successfully employed for monitoring the concentration of stabilizers in an electroless Ni plating bath. To demonstrate this, the following sections will discuss the determination of Pb with the Bi drop electrode and the determination of Bi and Sb(III) with the scTRACE Gold electrode.

Pb determination with the Bi drop electrode

Lead is one of the most efficient stabilizers used in electroless Ni baths. Typically, EN plating baths contain approximately 1 mg/L Pb.

The Hg-free Bi drop electrode is used in this application example. Due to the method’s working concentration range (0.5–25 µg/L), the bath sample must first be diluted for accurate results. The determination of Pb concentration is carried out by anodic stripping voltammetry (ASV) in 0.1 mol/L citric acid. After a series of 10 consecutive measurements, the recovery rate was reported between 94% and 101%, and the relative standard deviation was below 3%. The fully automated MVA-22 system (Figure 2) is recommended to guarantee optimum repeatability and reproducibility.

The results of Pb determination with the Bi drop electrode in an electroless Ni plating bath sample (NB1) containing 0.3 mg/L Pb are presented in Figure 4.

In Figure 5, recovery rates obtained from two different electroless Ni plating baths (NB1 and NB2) spiked with different concentrations of Pb (0.1 mg/L, 0.3 mg/L, and 1.2 mg/L) are presented.

Bi and Sb(III) determination with the scTRACE Gold electrode

The growing need for consumer products that are free of potentially hazardous substances is driven by increasingly strict government regulations around the world. This trend is likely to continue in the future. One such regulation in the European Union is RoHS directive 2011/65/EU which requires the elimination of certain heavy metals from electrical and electronic equipment. In this directive, one of the regulated substances is lead.

This has many implications for EN plating processes in which lead is used as a stabilizer because small amounts of Pb are co-deposited during the deposition of Ni. To comply with these regulations, the plating industry has successfully found acceptable lead-free alternatives (e.g., bismuth and antimony) which can be used as stabilizers in the electroless Ni plating process. However, the concentration of bismuth or antimony still has to be monitored in the plating bath to maintain optimal conditions for EN plating.

Determination of Bi and Sb(III) in electroless Ni plating baths can be achieved with the scTRACE Gold, one of the Hg-free sensors from Metrohm. The determination is carried out by anodic stripping voltammetry (ASV) in acidic electrolyte using the fully automated MVA-22 system (Figure 2).

The recovery rate is between 103% and 106% for Bi, and between 93% and 110% for Sb(III). The relative standard deviation is below 4% for Bi, and below 8% for Sb(III) in a series of 10 consecutive measurements. The main advantages of this approach are high reproducibility and the innovative sensor itself, which is maintenance-free and cost efficient.

Examples of the voltammetric determination of Bi and Sb with the scTRACE Gold in an electroless Ni plating bath are presented in Figure 6 and Figure 8, respectively. In Figure 7 and Figure 9, recovery rates obtained from two different electroless Ni plating baths (NB1 and NB2) spiked with different concentrations (0.1 mg/L, 0.3 mg/L, and 1 mg/L) of Bi and Sb(III) are presented.

Summary

Electroless nickel plating processes use various stabilizers to control the plating rate and prevent uncontrolled bath decomposition. One of the most efficient stabilizers used is Pb, though it has fallen out of favor in recent years due to stricter regulations. In its place, other suitable materials such as Bi and Sb(III) are used to stabilize the EN plating baths.

As the stabilizer concentration must be kept at a constant level, monitoring the stabilizer concentration is therefore essential for an optimal plating process. One of the best ways to do so is by using voltammetric analysis (VA). Mercury-based VA sensors were popular because of their sensitivity, automatically renewable and reproducible electrode surface, and wide cathodic polarization range. However, mercury is toxic and damaging to the environment, necessitating development of Hg-free VA sensor alternatives.

Metrohm offers several Hg-free electrodes used for voltammetric determination of heavy metals. The suitability of the Bi drop electrode for the determination of Pb and the scTRACE Gold electrode for measuring Bi and Sb(III) in electroless Ni plating baths has been demonstrated. Several benefits are gained by using these mercury-free sensors for voltammetric analysis.

Benefits of using Hg-free sensors from Metrohm to determine stabilizer content in EN plating baths:

- Long lifetime of the maintenance-free sensors

- Excellent analytical performance

- Low costs of ownership

- Compliance with legal regulations

- No use of metallic mercury

- First class support

- Modularity of the 884 Professional VA system and possibility for automation

References

[1] Sudagar, J.; Lian, J.; Sha, W. Electroless Nickel, Alloy, Composite and Nano Coatings – A Critical Review. Journal of Alloys and Compounds 2013, 571, 183–204. DOI:10.1016/j.jallcom.2013.03.107

[2] Loto, C. A. Electroless Nickel Plating – A Review. Silicon 2016, 8 (2), 177–186. DOI:/10.1007/s12633-015-9367-7

[3] Bonin, L.; Vitry, V.; Delaunois, F. Inorganic Salts Stabilizers Effect in Electroless Nickel-Boron Plating: Stabilization Mechanism and Microstructure Modification. Surface and Coatings Technology 2020, 401, 126276. DOI:10.1016/j.surfcoat.2020.126276

[4] Barón-Jaimez, J.; Joya, M. R.; Barba-Ortega, J. Anodic Stripping Voltammetry – ASV for Determination of Heavy Metals. J. Phys.: Conf. Ser. 2013, 466, 012023. DOI:10.1088/1742-6596/466/1/012023

[5] Švancara, I.; Mikysek, T.; Sýs, M. Polarography with Non-Mercury Electrodes: A Review. Electrochemical Science Advances n/a (n/a), e2100205. DOI:10.1002/elsa.202100205

Your knowledge take-aways

Brochure: 884 Professional VA – Universal system solution for voltammetry and CVS

Brochure: Bi drop electrode – A novel non-toxic alternative for metal analysis down to the ppt range

Brochure: scTRACE Gold – Simple and reliable determination of arsenic in water

Share via email

Share via email