Silicon semiconductor devices are manufactured on highly polished wafers. Scratches and other imperfections on the wafer could affect the performance of the final product. Therefore, surface preparation is a key step to obtain clean, mirror polished, undamaged silicon surfaces.

Chemical cleaning is a proven method used here to remove contaminants from the wafer surface. The most common process, «RCA clean», cleans wafers via two consecutive standard solutions. The standard cleaning 1 «SC1» bath (or ammonia peroxide- mixture «APM») is composed of NH4OH and H2O2. The standard cleaning 2 «SC2» bath is made of HCl and H2O2. The key factors for efficient wafer cleaning are bath residence time and optimum chemical concentration in the cleaning baths. Using near-infrared spectroscopy to monitor the major SC1/SC2 bath constituents inline guarantees increased wafer yields while decreasing defect density.

Efficient silicon wafer cleaning requires optimal process control to ensure an increase in product throughput without additional defects, while increasing production rates and profitability at the same time.

The SC1 bath removes particles, films, and organic residue from the wafer, and forms a thin oxide layer on the surface. However, transition metal hydroxides may also remain on the wafer surface. That is when the SC2 bath becomes essential in the post-chemical mechanical planarization «CMP» cleaning sequence.

SC2 baths are acidic, helping to remove surface alkali and transition metals. This cleaning process leaves a thin passivation layer on the surface of the wafer to avoid future contamination.

The smaller the semiconductor device, the more difficult it is to remove the small particles from the surface of the silicon wafer. Therefore, semiconductor manufacturers perform the standard cleaning steps in a wet bench inside a cleanroom to control the environment and avoid further contamination. This setup leaves very limited space to install an analysis system. Additionally, any chemical handling should be avoided inside the cleanroom area to increase personal and production safety, and to avoid contamination of the wafers.

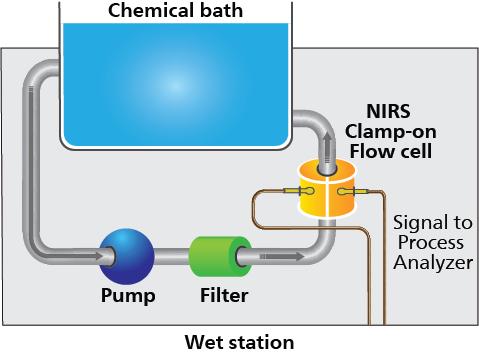

A safer, more efficient, and faster way to monitor multiple parameters simultaneously in standard cleaning baths is via inline analysis with reagent-free near-infrared spectroscopy (NIRS), as shown in Figure 1.

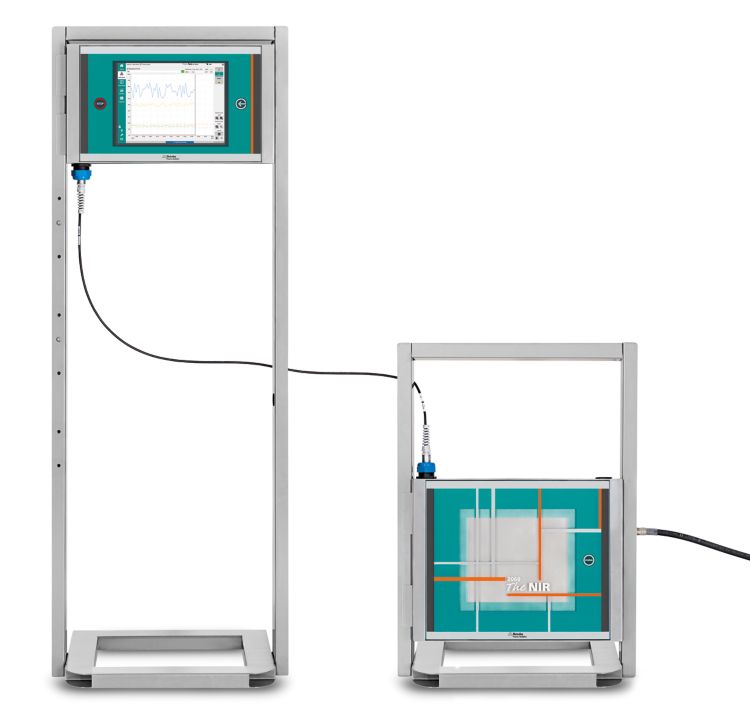

The 2060 The NIR-R Analyzer by Metrohm Process Analytics (Figure 2) enables comparison of «real-time» spectral data from the process to a reference method (e.g., titration, HPLC, IC) to create a simple, yet indispensable calibration model for the standard clean baths.

Wavelength range used: 800–1300 nm. Reference method: ion chromatography.

When cleanroom space is limited, the NIR cabinet from the 2060 The NIR-R Analyzer can be mounted outside the cleanroom in the subfab core facility or simply beneath the wet bench embedded in the processing unit/tool itself. The distance between the instrument and the sample points (up to five possible with one NIR cabinet) can be hundreds of meters apart and simply interfaced to the instrument with low-dispersion optical fibers.

All process baths have a circulation loop made of PFA tubing. The flow cell, designed and customized by Metrohm Process Analytics, can be clamped on to these tubes for easy installation, so there is no need to modify the existing setup (Figure 1). Just clamp the flow cell on and start measuring.

Figure 3 illustrates a trend chart obtained through NIRS for a standard clean 1 (SC1) bath containing ammonia (NH3) and hydrogen peroxide (H2O2). Bath changes are triggered based on predefined concentration or time limits, highlighting the significance of monitoring both parameters. Continuously monitoring the ammonia and hydrogen peroxide levels is crucial for maintaining the integrity of the cleaning process within specified limits.

In this application, the goal was to monitor NH3 dosage within the SC1 bath to improve recirculation and ensure fast and uniform mixing. Each NH3 injection shows a definite peak followed by a small decrease of <0.10 wt% (Figure 3), demonstrating the capacity of NIRS to detect even tiny concentration differences.

Compared to traditional analytical methods, the 2060 The NIR-R Analyzer offers significant advantages in terms of precision and frequency of measurements, allowing for continuous monitoring and precise control of the SC1 bath.

Table 1. Slurry measurement parameters.

| Parameters | Temperature [°C] | Range [wt %] | |

|---|---|---|---|

| SC1 | NH4OH | 65 ± 3°C | 0–1 |

| H2O2 | 65 ± 3°C | 0–2 | |

| SC2 | HCl | 35 ± 3°C | 0–1.5 |

| H2O2 | 35 ± 3°C | 0–5 | |

| SC2 | HCl | RT–70°C | 1–5 |

| H2O2 | RT–70°C | 1–10 | |

An appropriate range of samples covering the process variation is needed to build a calibration model. These samples will be analyzed via NIRS and via a reference method. The precision of the NIRS data is directly correlated to the precision of the reference method.

Other process applications are available for the semiconductor industry like: copper, sulfuric acid, and chloride in acid copper baths, acidity in mixed acid etchants, and hydrofluoric acid etch, ammonium hydroxide, and hydrochloric acid in standard clean baths.

NIRS analysis enables the comparison of «real-time» spectral data from the process to a primary method (e.g., titration, Karl Fischer titration, HPLC, IC) to create a simple, yet indispensable model for process requirements. Improve semiconductor production control with the Metrohm Process Analytics 2060 The NIR-R Analyzer. This process analyzer can monitor up to five process points per NIR cabinet using the multiplexer option.

- Increased product throughput, reproducibility, production rates, and profitability (less wafer discarding).

- Efficient wafer cleaning by constantly monitoring the standard cleaning baths.

- More savings per measurement point, making results more cost-efficient.

- Safer production due to «real-time» monitoring and no exposure of operators to chemical reagents.

Share via email

Share via email

Download PDF

Download PDF