Thermal power plants require enormous amounts of water, using high purity steam at high pressure to rotate turbines. A separate cooling water circuit is implemented, helping to form a vacuum when the steam condenses after the turbines. Maintaining this vacuum with optimal condensation parameters is critical for the power plant efficiency.

The copper condensers are susceptible to corrosion by ammonia (NH3). Small cracks in the condenser combined with the large pressure differential between the steam circuit and the cooling water circuit will contaminate the high purity water in the boiler, causing major problems and necessitating a shutdown for plant maintenance. Monitoring NH3 online in cooling water with a process analyzer can signal early problems in a plant before significant intermediation is necessary.

This Process Application Note presents a way to closely monitor the NH3 concentration in cooling water of power plants to ensure protection of expensive company assets (e.g. pipes, boiler, and more) and helps to safeguard plant operations.

Thermal power plants require enormous amounts of water to convert energy from generated heat to electricity, using high purity steam at high pressure to rotate turbines. The steam loses energy and condenses, forming a vacuum after the turbines, and the re-condensed vapor is sent back to the boiler for reuse. Maintaining this vacuum with optimal condensation parameters is critical for the power plant efficiency.

Cooling water is used in a separate water circuit to exchange heat from the condenser to the ambient surroundings. Water sources for cooling can range from seawater, lakes, and rivers, to re-treated municipal wastewater (MWW). The cooling water circuit, discussed in other Metrohm Process Application Notes (AN-PAN-1013, AN-PAN-1038), is classified as either once-through or recirculating (dry cooling is not discussed here). The growing number of environmental guidelines and thermal discharge limits has forced many plants to use closed recirculating cooling water circuits, reducing the cooling water needs by about 95% compared to once-through cooling systems. The heat from the condenser can dissipate in a number of manners, most commonly by an evaporative cooling tower (Figure 1). Only small amounts of makeup water are required to replace evaporative, drift, and blowdown losses in recirculating cooling water circuits. The cooling water chemistry is primarily maintained to inhibit scale formation and microbial growth (fouling) as well as control corrosion.

Copper (Cu) alloys are now used almost exclusively in condensers of the water-steam circuit. The drawback is the susceptibility of copper and its alloys to corrosion by NH3. Ammonia is also nutritional for microbes, which cause biological fouling. Ammonia stripping towers can be implemented on site to remove a significant percentage of NH3 via water-to-air stripping, otherwise water treatment is necessary. The cooling tower itself can strip the volatile NH3 at optimal pH levels. According to the Electric Power Research Institute (EPRI), in systems with copper alloys an upper limit of 2 mg/L NH3 must be adhered to in order to prevent severe corrosion. The result is increased Cu concentration in effluents or other discharges, which is of environmental concern. Corrosion can also cause leaks and catastrophic failure in the piping. Small leaks and cracks combined with the large pressure differential between the steam circuit and the cooling water circuit will contaminate the high purity water in the boiler, causing major problems and necessitating a shutdown for plant maintenance.

Corrosion of Cu and its alloys can be inhibited by adding triazoles to form sparingly soluble compounds on the surface of the metal. Routine system chlorination against biological fouling will reduce ammonia levels somewhat as chloramines are formed. Corrosion products and other impurities can be removed by chemical cleaning. However, it is clear that ammonia is detrimental to the cooling water circuit and must be treated or otherwise removed before Cu corrosion can occur. Metrohm Process Analytics offers multiple online process analyzers which can measure NH3 in cooling water of power plants, alerting the Chemical Distribution System (CDS) to add more corrosion inhibitors, chlorine, or other treatment chemicals to the circuit before extreme damage can occur.

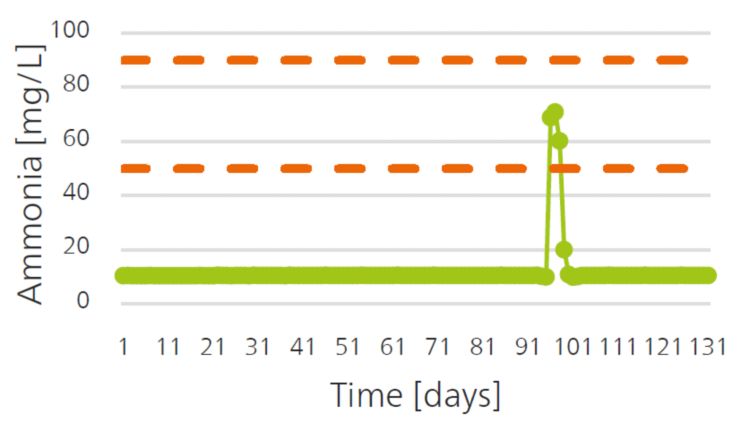

Online monitoring of the ammonia content is possible with either the 2060 Process Analyzer or with the 2026 Titrolyzer from Metrohm Process Analytics (Figure 3). An ammonia ion-selective electrode (NH3-ISE) is used in this application for quick, simple, and accurate online analysis of NH3 concentrations in cooling water. After sampling, a Total Ionic Strength Adjustment Buffer (TISAB) solution is added to adjust the pH to 11 or higher, and the NH3 concentration in the sample is determined using the dynamic standard addition method.

Typical range

0–100 mg/L NH3

Lower concentrations of ammonia can be analyzed online with colorimetric or ion chromatographic methods, also available from Metrohm Process Analytics. Other online applications are available for the energy and power industry such as: silica in boiler feed water, calcium and sulfate in the flue-gas desulfurization process, boric acid in cooling water Pressurized Water Reactors (PWRs), ultratrace measurements of iron (Fe) and Cu, rich/lean amine concentration and CO2 captured in Carbon Capture Plants, and many more.

- Safe working environment and automated sampling

- Protect valuable company assets (e.g. pipes, PWR, and turbines, which are prone to corrosion)

- Save money by reducing downtime: analyzer sends alarms for out-of-specification values which inform the operator sooner

Share via email

Share via email

Download PDF

Download PDF